Product Features

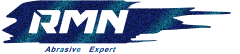

Rough Grinding

During rough grinding, excess material is removed from the blank while maintaining its approximate geometric shape and surface roughness.

Rough grinding enhances grinding efficiency, reduces tool wear, protects and lubricates the workpiece, eliminates burrs and sharp edges, rounds corners, removes oxide scale and rust, thereby improving the metal surface for fine grinding by leaving a balanced margin. This ensures stable dimensions and better smoothness in precision grinding.

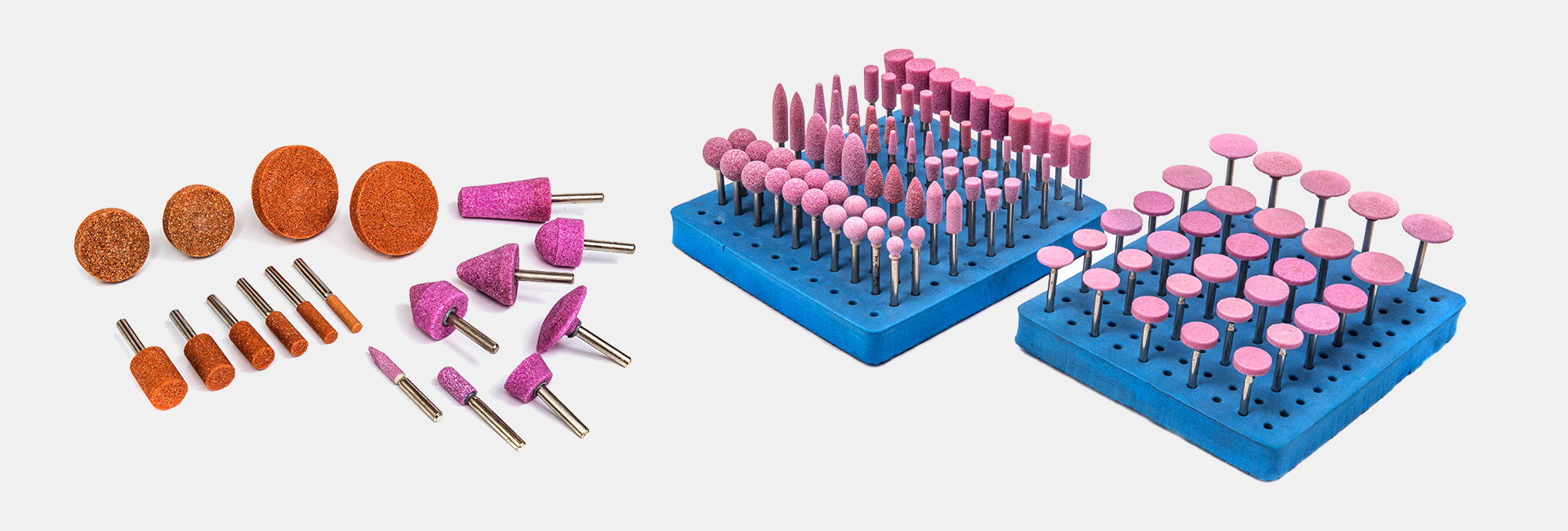

Read MoreFine Grinding

Polishing is a crucial step that follows grinding and serves to prepare the surface for further refinement. The ultimate objective is to attain an equivalent level of smoothness as achieved through grinding, while simultaneously preserving the utmost precision in terms of geometric shape and minimizing any potential presence of fine cracks.

Read MoreIf you have any questions about our products and services, please do not hesitate to contact us. Our team will reach you within 12 hours!

We offer an expansive selection of customization options that match the unique demands of the OEM market.

Quality control is always the highest priority, upholding strict standards in every step of the manufacturing process.

Navigation

RIKEN MN COATED ABRASIVES CO., LTD is branch company of ZIBO RIKEN MT COATED ABRASIVES CO., LTD. Which is a professional manufacturer to supply the top grade coated abrasives in China.

Product Categories

Automotive Aftermarket

CopyRight © 2023-2024 RIKEN MN COATED ABRASIVES CO., LTD. All rights reserved Sitemap All tags Designed by Zhonghuan Internet